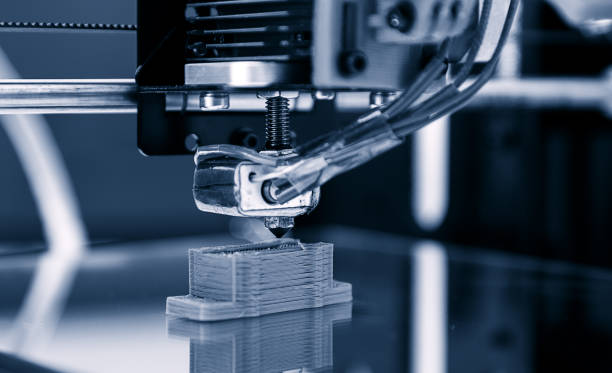

3D printing has emerged as a groundbreaking technology that is reshaping a multitude of industries, and the field of electronics is no exception. From rapid prototyping to custom components, 3D printing is enabling advancements that were previously unimaginable. This article delves into the transformative role of 3D printing in the electronics sector, exploring its multiple benefits and applications.

Rapid Prototyping and Development

One of the most significant ways 3D printing is revolutionizing electronics is through rapid prototyping. Engineers can now create and test prototypes within hours instead of weeks. This ability to produce quick iterations accelerates the development process, allowing for faster identification of flaws and more efficient improvements. The cost-effectiveness of 3D printing also means that multiple designs can be tested without breaking the budget, offering unparalleled flexibility in product development.

Customization and Personalization

Another revolutionary aspect of 3D printing in electronics is the level of customization it allows. Traditional manufacturing processes are often limited by the need for mass production. In contrast, with 3D printing, it is possible to create customized electronic components that meet specific needs of individual projects. Whether it’s a uniquely shaped circuit board or a tailored enclosure, the possibilities are virtually limitless. This opens up new doors for personalized consumer electronics and bespoke industrial solutions.

Cost Reduction and Efficiency

3D printing can significantly lower manufacturing costs in multiple ways. First, it reduces the need for expensive molds and tooling, which are traditionally required for producing electronic components. Second, additive manufacturing minimizes waste, as materials are only used where necessary. This efficiency not only lowers costs but also makes the process more environmentally friendly. Companies can thus enjoy greater profit margins while also appealing to eco-conscious consumers.

Enhanced Functionality and Innovation

With 3D printing, the integration of complex functionalities into electronic devices is simpler than ever. Multilayered circuits and intricate designs that would be challenging or impossible to achieve with conventional methods can now be produced effortlessly. This enhanced functionality leads to innovative products with superior performance characteristics. Consequently, industries such as wearable tech, medical devices, and consumer electronics are experiencing a surge in novel, high-performance products.

The Impact on Supply Chains

The emergence of 3D printing also significantly impacts supply chains in the electronics industry. Traditional supply chains, often long and complex, can be drastically shortened. Electronic components can be produced locally and on-demand, reducing the need for excessive inventory and long shipping times. This not only minimizes logistics costs but also enhances the agility of manufacturers, enabling faster response to market changes and customer demands.

Conclusion

3D printing is undoubtedly a game-changer in the realm of electronics. From the acceleration of prototyping and development to the creation of customized components, and from significant cost reductions to the enhancement of product functionality, 3D printing offers myriad benefits. Furthermore, its impact on supply chains adds another layer of efficiency and responsiveness. As the technology continues to evolve, its influence on the electronics industry is poised to grow even further.

FAQs

-

What types of electronic components can be 3D printed?

Virtually any electronic component, including circuit boards, enclosures, connectors, and even some integrated systems, can be 3D printed. -

How does 3D printing reduce production costs?

3D printing eliminates the need for expensive molds and tooling, reduces material waste, and allows for the local production of parts, thereby lowering overall costs. -

Is 3D printing environmentally friendly?

Yes, 3D printing is more environmentally friendly compared to traditional manufacturing processes because it generates less waste and often uses fewer materials. -

Can 3D printing be used for mass production in electronics?

While 3D printing is excellent for rapid prototyping and small batch production, advancements in the technology are increasingly making it feasible for larger-scale manufacturing runs. -

What industries benefit the most from 3D printing in electronics?

Industries such as wearable technology, medical devices, aerospace, and consumer electronics are some of the primary beneficiaries of 3D printing advancements in electronics.